赛马会创新楼是香港理工大学设计学院及赛马会社会创新设计院的总部。该大楼高十五层,面积15,000平方米,可容纳超过1800位学生和教职员。大楼以设计教学及创新用途为主,设施包括:设计室、研究室和工作间、展览廊、多功能教室、阶梯教室以及公共休闲区等。香港理工大学外观统一却各有特点的教学楼中分布着各大院系,50年以来,理大一直致力于打造城市化校园。赛马会创新楼的建立创造了新的城市空间,丰富了校园生活的多样性,展现了面向未来的无限活力。

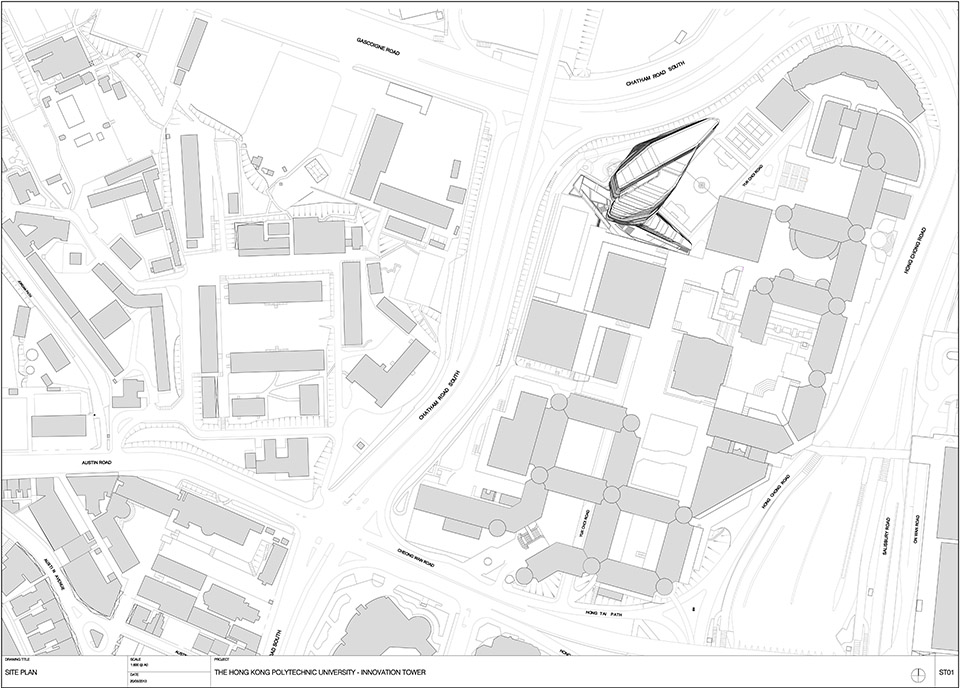

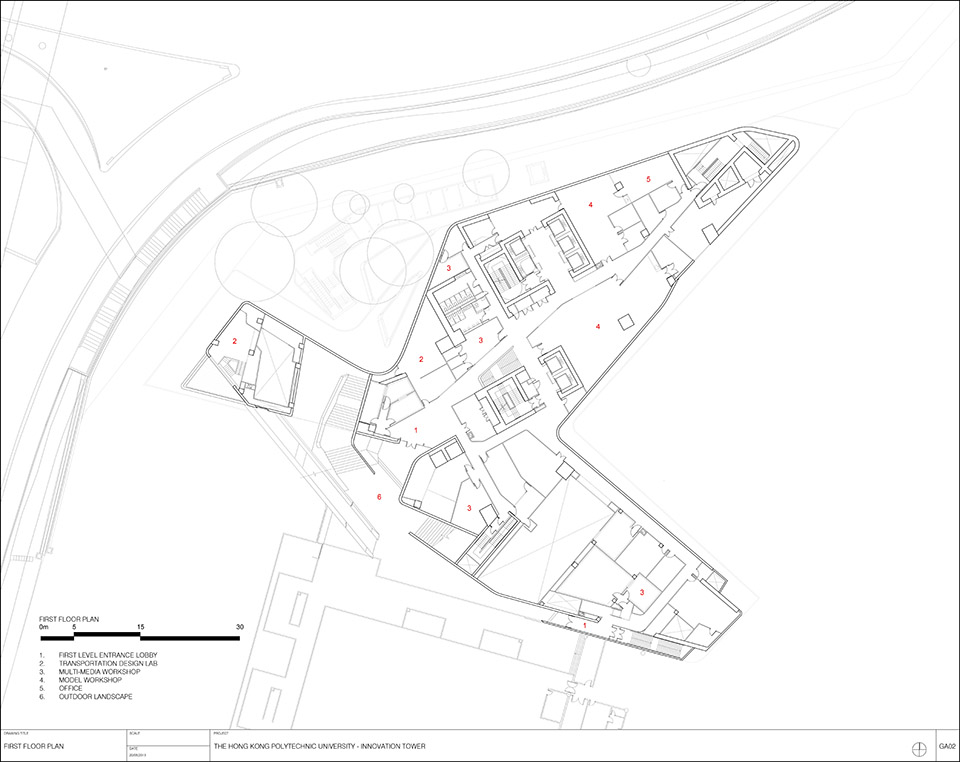

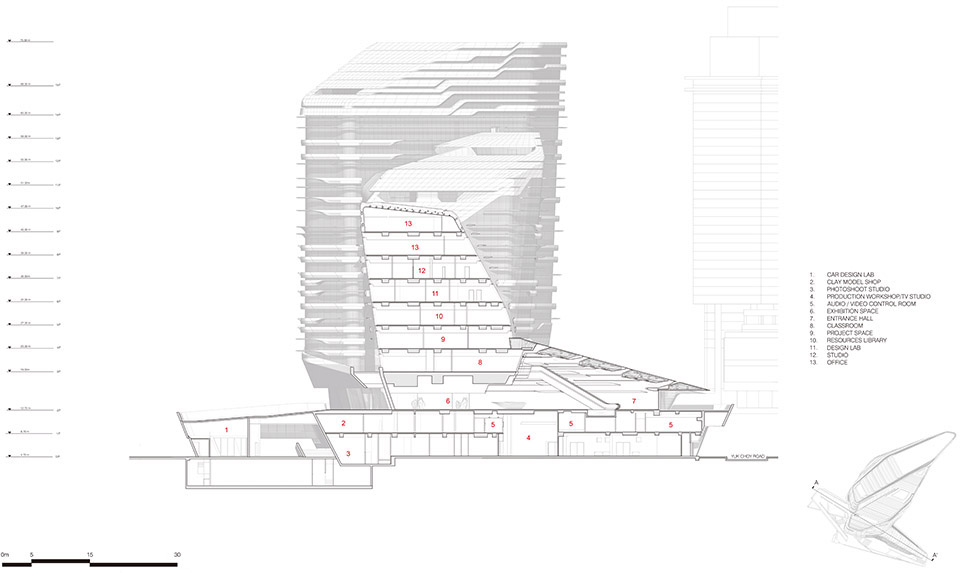

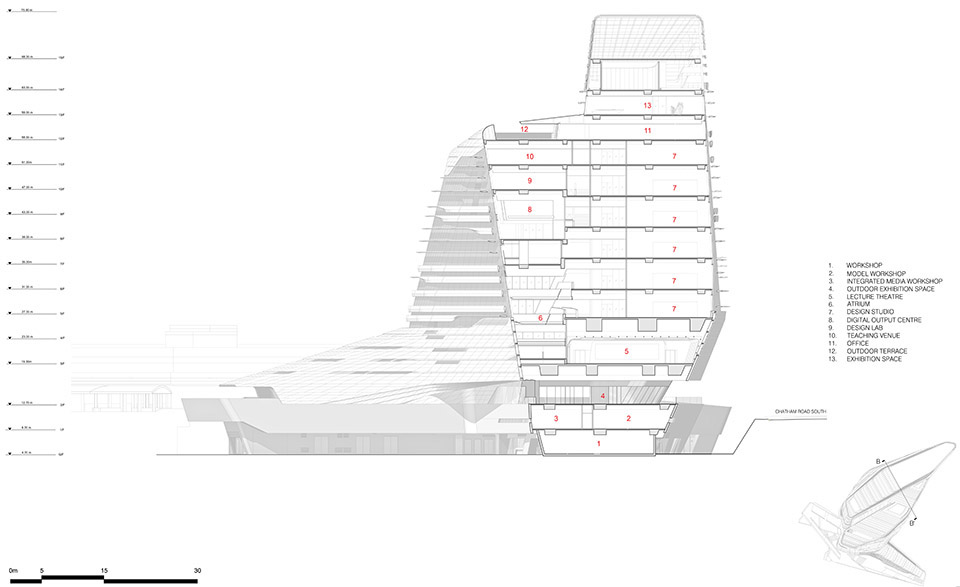

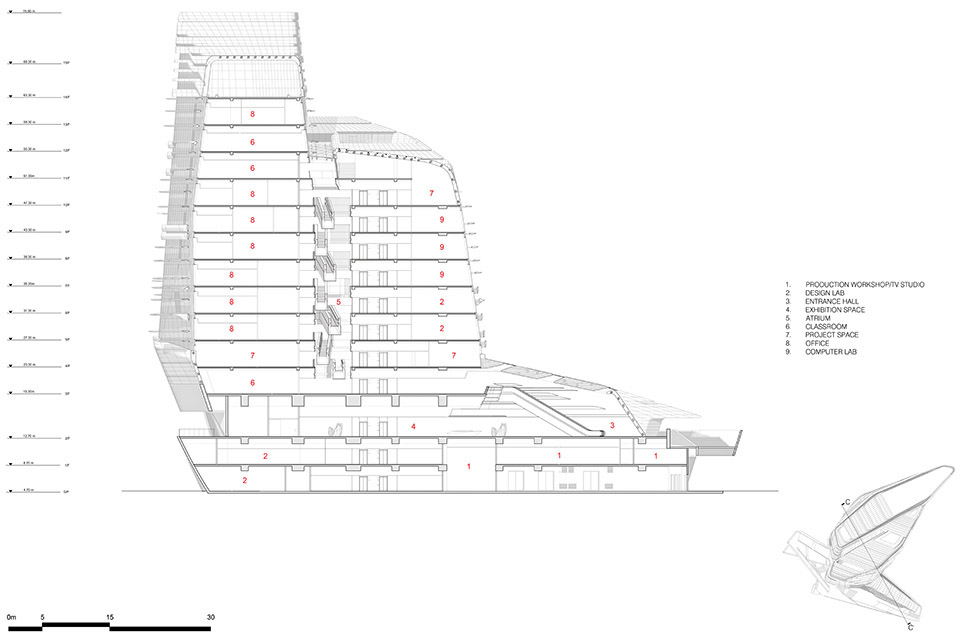

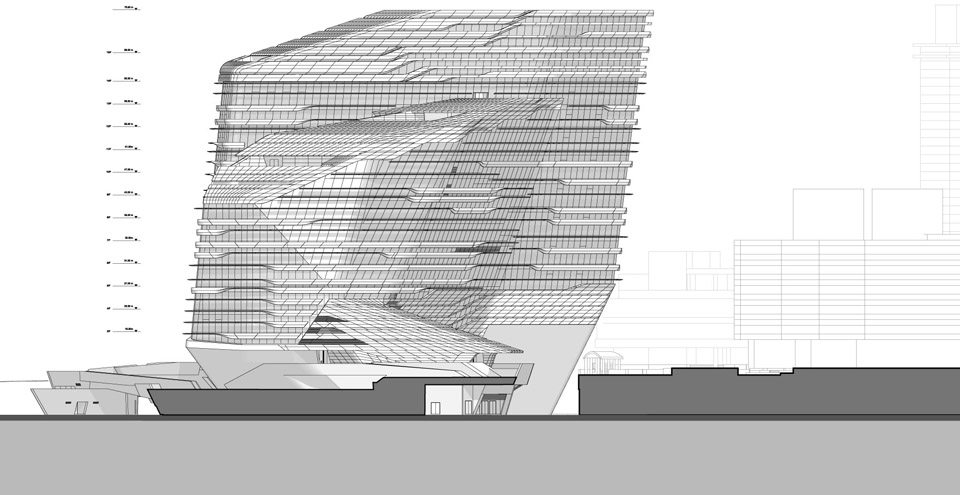

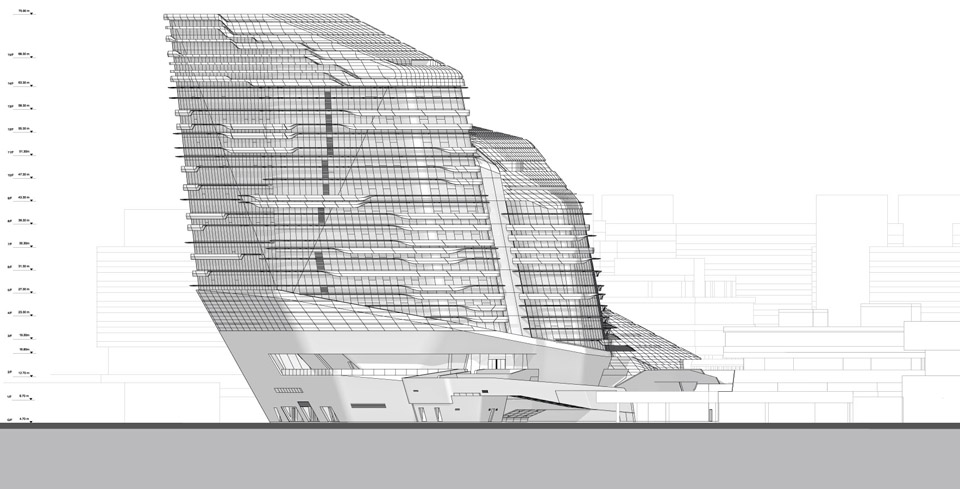

赛马会创新楼坐落于理大校园东北角一片狭窄而不规则的地块上,南端紧邻足球场,北端是九龙走廊高速公路立交桥。大楼延伸至校园中心,积极促进各院系之间开展多学科项目,加强与社区、政府、工业、民间组织和学术界的交流。赛马会创新楼的设计将塔/台的典型特征融合为更流畅的组合线条。不规则的内外庭院提供一个会面和交流的场所,同时也是大型展示区、工作室、阶梯教室和休闲设施之外的补充性设计。由于设计学院融合各个学科的特点,赛马会创新楼更好地营造了一个多学科环境和集体研究的氛围,不同的思想和创新在这里碰撞出新的火花。学生、教职工和参观者乘着15层楼梯可看到设计室、工作间、研究室、展览廊和活动区。室内的玻璃和开放的空隙提高了透明度和连通性,而循环路线和公共区域方便了学生群体与大师们的交流互动。

Jockey Club Innovation Tower

Hong Kong Polytechnic University

The Jockey Club Innovation Tower (JCIT) is home to the Hong Kong Polytechnic University (PolyU) School of Design, and the Jockey Club Design Institute for Social Innovation.

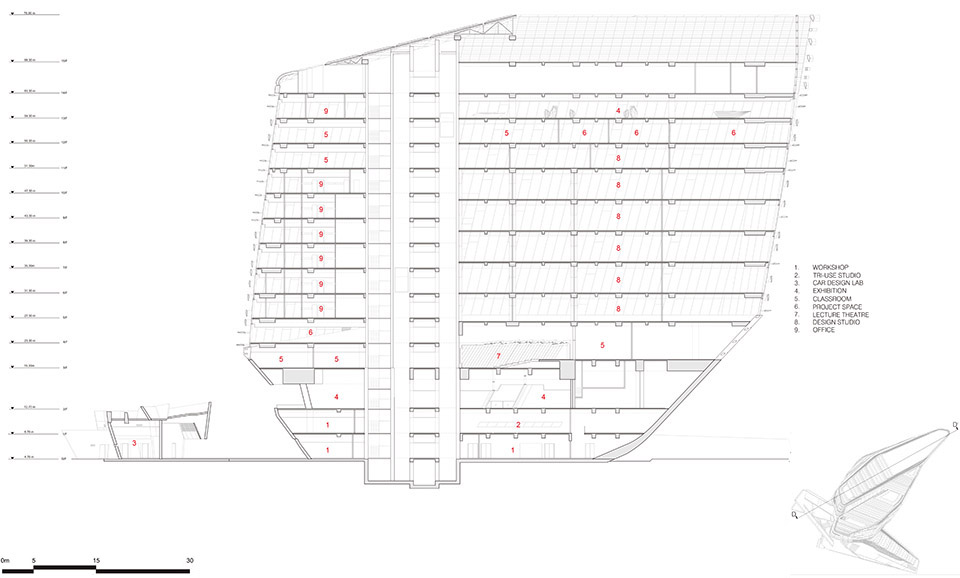

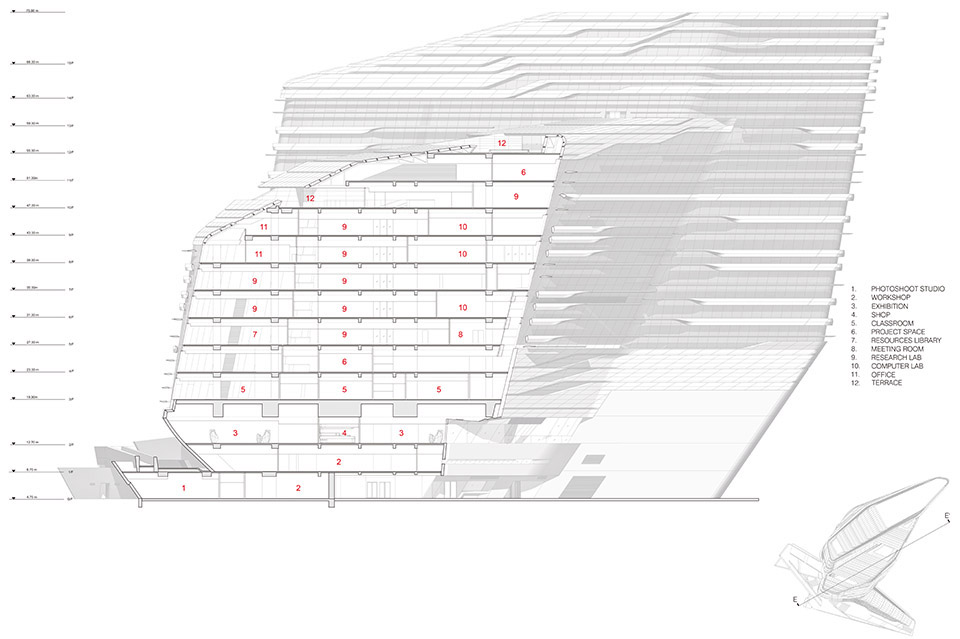

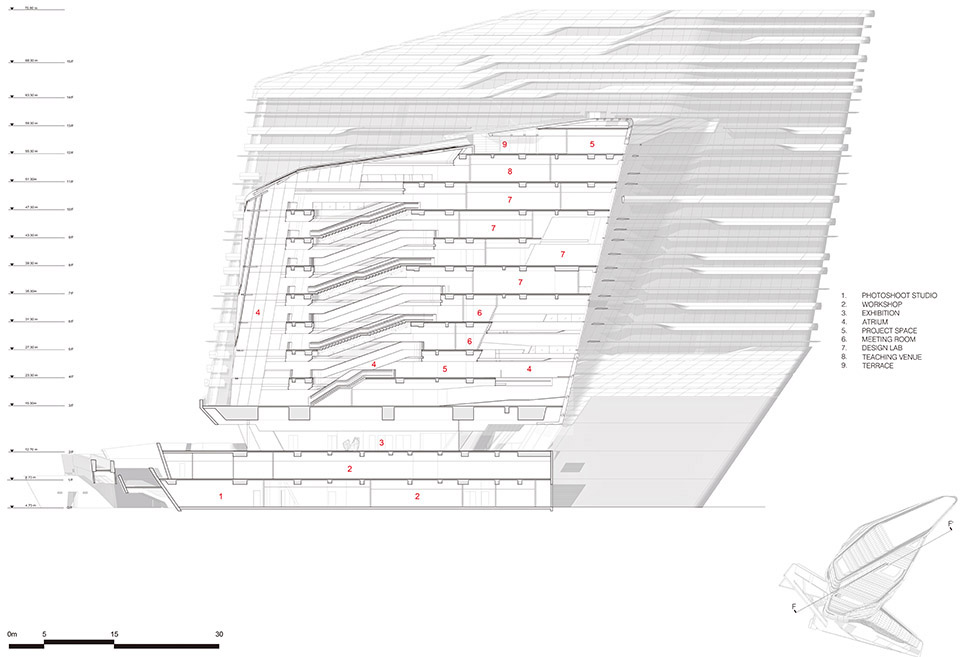

The 15-storey, 15,000 sq. m. tower accommodates more than 1,800 students and staff, with facilities for design education and innovation that include: design studios, labs and workshops, exhibition areas, multi-functional classrooms, lecture theatre and communal lounge.

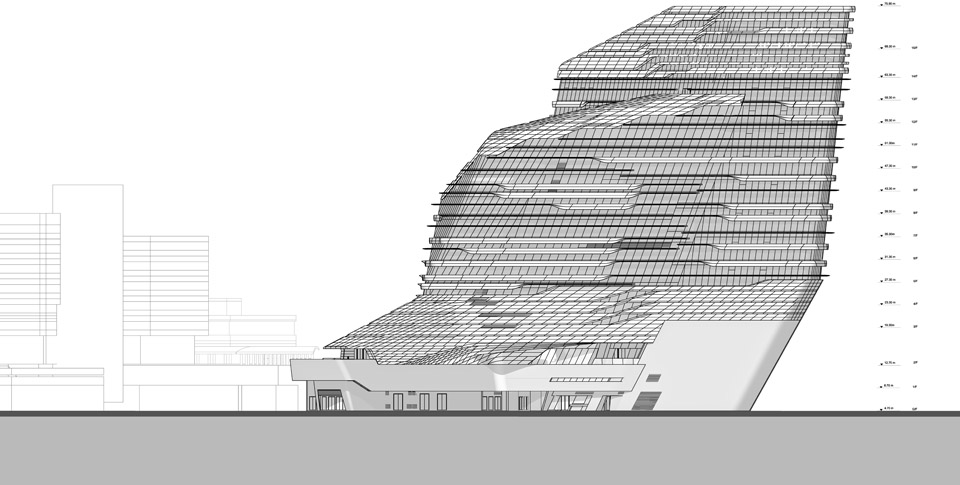

The Hong Kong Polytechnic University campus has developed its urban fabric over the last 50 years with the university’s many faculties housed in visually coherent, yet very different buildings. The JCIT creates a new urban space that enriches the diversity of university life and expresses the dynamism of an institution looking to the future.

Located on a narrow, irregular site at the northeastern tip of the university campus (bordered by the university’s football ground to the south, and the Chatham Road/Kowloon Corridor motorway interchange to the north), the JCIT is connected to the heart of the campus; encouraging the university’s various faculties and schools to develop multidisciplinary initiatives and engagement with the community, government, industry, NGO’s and academia.

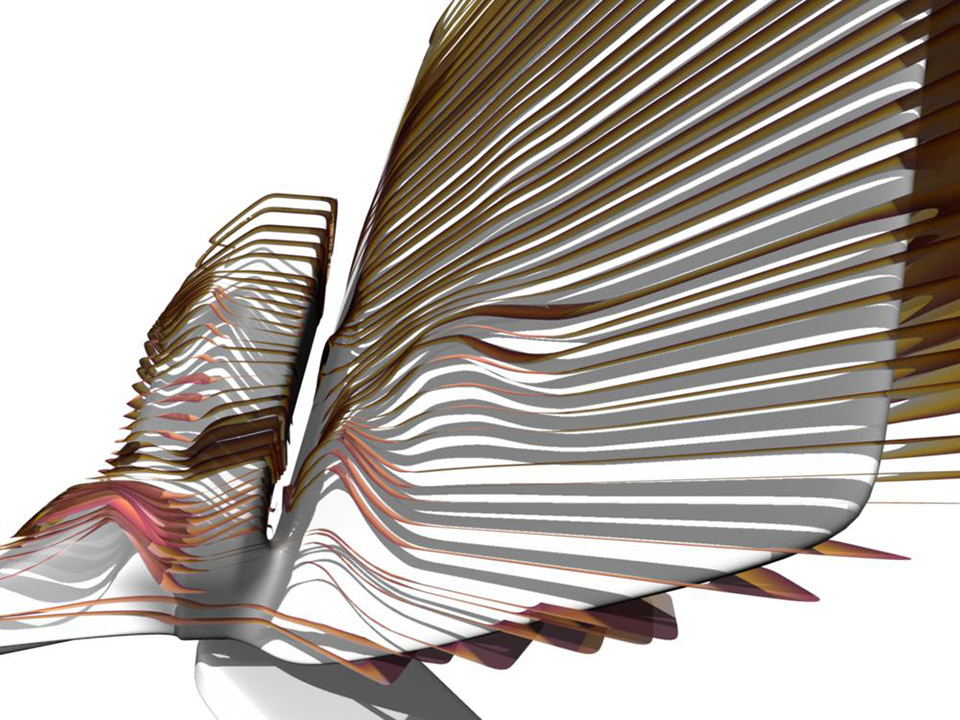

The JCIT design dissolves the typical typology of the tower/podium into a more fluid composition. Interior and exterior courtyards create informal spaces to meet and interact, complementing the large exhibition forums, studios, theatre and recreational facilities. The tower’s design promotes a multidisciplinary environment by connecting the variety of programs within the School of Design; establishing a collective research culture where many contributions and innovations can feed off each other.

Students, staff and visitors move through 15 levels of studios, workshops, labs, exhibition and event areas within the school. Interior glazing and voids bring transparency and connectivity, while circulation routes and communal spaces have been arranged to encourage interaction between the many learning clusters and design disciplines.

With its contribution of HK$249 million towards the construction of

JCIT, The Hong Kong Jockey Club Charities Trust also funds the Jockey Club Design Institute for Social Innovation.

Here is more information form the architects:

来自扎哈哈迪德事务所的更多信息:

Engineering by Ove Arup & Partners, Hong Kong Ltd.

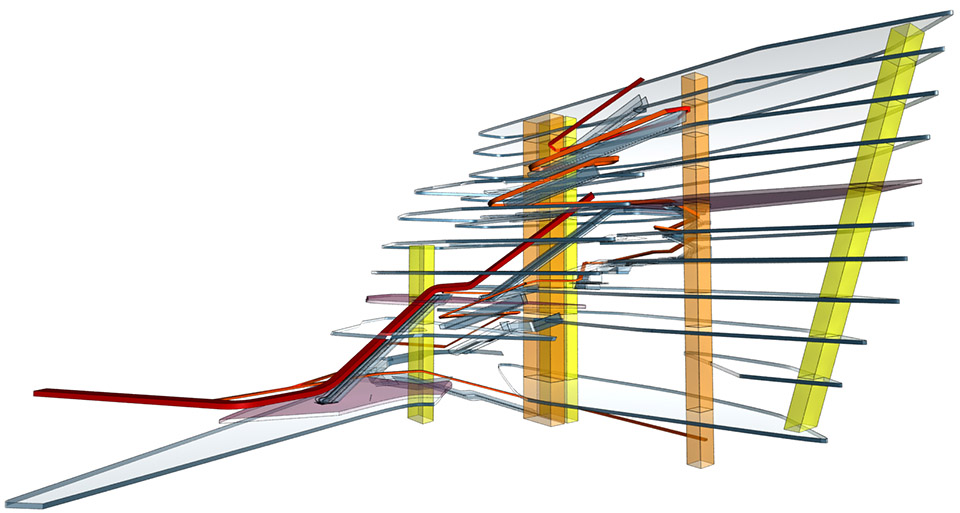

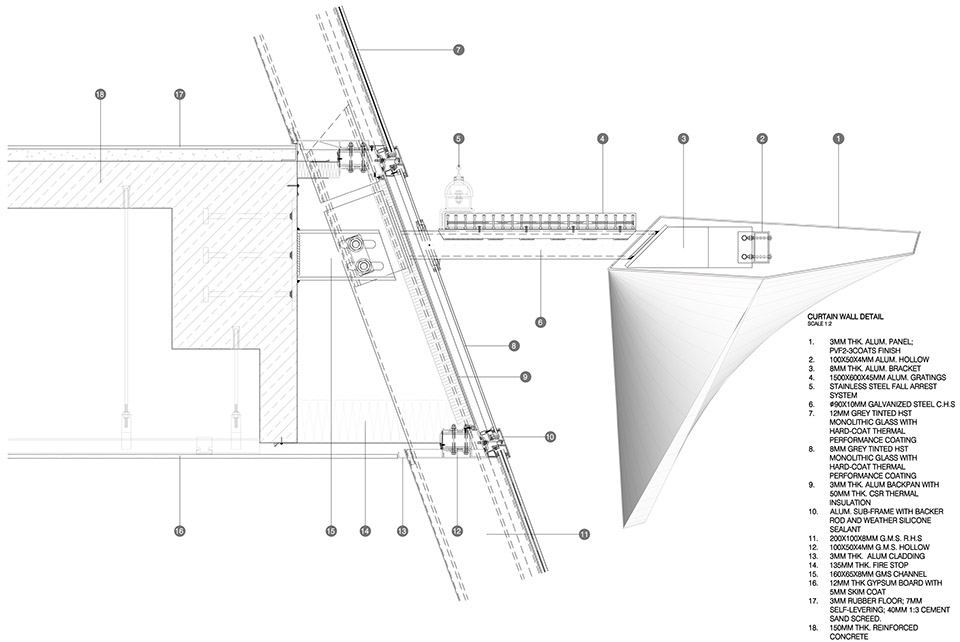

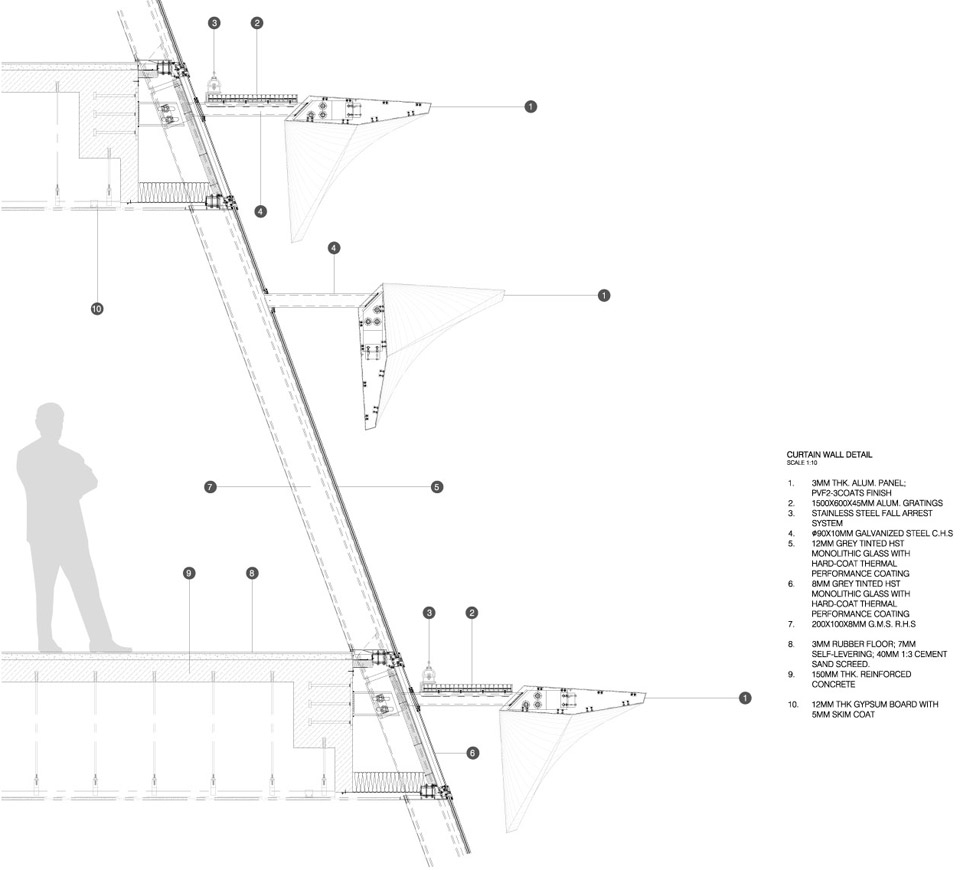

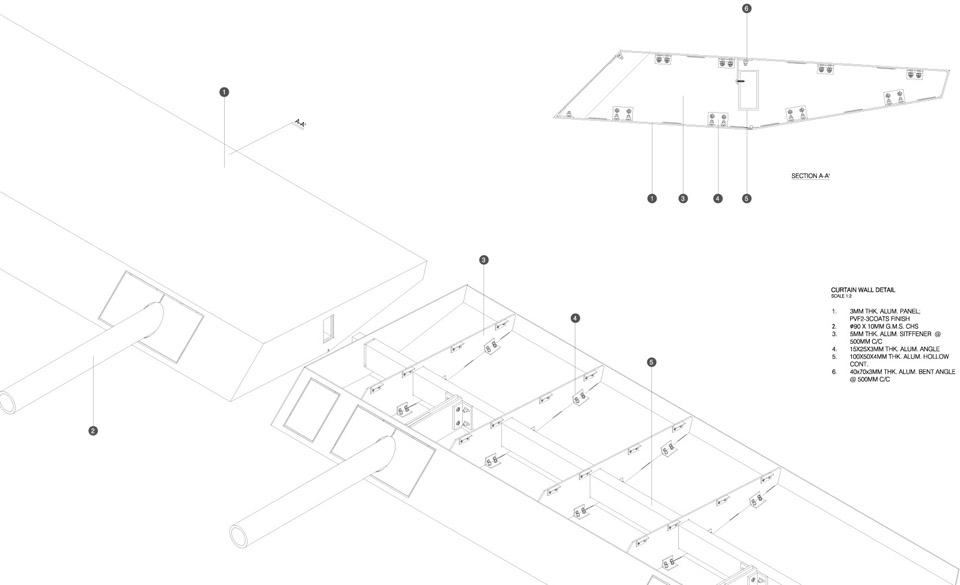

Three dimensional drafting and Building Information Modelling (BIM) was used resolve the evolving geometry of Jockey Club Innovation Tower. Arup performed the role of structural and building services engineer to help realise the design by Zaha Hadid Architects. BIM was integral to the design and construction of this three dimensionally irregular-shaped building; enabling clash-analysis with building elements and services, providing an efficient mode of communication between the architectural, structural, building services and facade engineers.

“The façade is one of the key elements of this building. Weekly design workshops were often focused on the verification of design information provided by the architect against BIM information built from the onsite surveying of the structural elements, building services and façade structures,” an Arup spokesperson said. “BIM frequently highlighted design issues which would have been impossible for either the consultants or contractor to detect using traditional graphical projection drawings. With the assistance of BIM, thecoordination was more efficient and avoided a lot of abortive

site works.”

Arup also used design software in Etabs to carry out the structural analysis. With the coordinates from the Etabs model, the engineers produced an outline of the structure to communicate with the Zaha Hadid Architects’ 3-Dimensional computer model.

The structural engineering Innovation Tower included the tower overhanging the footpath on and the raked elevation north of the site, with foundations not permitted within the path. In response, Arup designed the superstructure to use three main cores and beam-column frames for lateral load and eccentric tower loads. Raking columns are used in some areas to handle loads from tilting. Discrete transfer beams have been used on the third floor to free up the lower two levels as much as possible.

The foundation of the tower used 54 large diameter bored piles, which minimised construction vibration and ground settlement that could affect adjacent buildings, and added capacity to resist very large loads arising from the tilting disposition of the tower. During construction, Arup established alarm monitoring levels during basement excavation in case of nearby settlement.

With a unique building geometry, Arup maintained Zaha Hadid Architects’ design intent for the curved 3D façade by investigating several alternative cladding materials including fibre reinforced plastic, tensile fabric and aluminium. A unique three dimensional metal cladding was selected. A multiple layer of panelling allows the top layer of cladding to have open joints, while a hidden lower layer provides functional weatherproofing and drainage functions.

The key façade design challenge on the project was the detailing and interface resolution of the curved 3D façade cladding. A series of catwalks were designed behind the façade cladding with removable access panels to the interior to access glass that could not be reached by the building maintenance unit’s normal operation. The panels are located in spaces which can be safely closed by facilities management staff while the building is open.

Arup implemented differential pressure controller valves for the chilled water system for stable hydraulic performance and convenience for future alterative works. The chilled water circuit design allows the full and part load performance of chillers to be measured according to a process set out in a technical paper by Professor Francis Yik, from the university’s Department of Building Services Engineering.

Continued

The building has also incorporated energy efficient features in building services installations, including evaporative cooling towers for water cooled chillers, energy wheels provided to the primary air unit to enable energy recovery between exhaust air and fresh air intake, and carbon dioxide sensors in general teaching facilities and offices to modulate the volume of fresh air supply.

Built-in thermostats sense average room air temperature from a sample of air induced into the unit. An energy humidity recovery ventilator is also included instead of a heat wheel to allow sensible and latent waste heat to be recovered. A central control and monitoring system manages all lighting and mechanical equipment to optimise energy saving.

Arup used BIM to integrate the building services design with the building’s unique internal geometries which could not be fully represented with conventional 2-dimensional drawings.

Client

The Hong Kong Polytechnic University (Campus Development Office) Location11 Yuk Choi Road, Block V,The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong

Description

The ‘Jockey Club Innovation Tower’ is a new building dedicated to the Hong Kong Polytechnic’s School of Design and its expansion. The faculty includes a broad range of design disciplines; with Industrial & Products Design, Visual Communication, Advertising, Digital Design and Environmental Design.

The building will provide over 15,000 square meters of net usable floor area to accommodate over 1,800 students and staff.

Funding

With the acknowledgement of a HKD $249 million donation from The Hong Kong Jockey Club in July 2011, the building has been subsequently renamed as the ‘Jockey Club Innovation Tower’

Architects

Design Architect

Zaha Hadid Architects (ZHA)

ZHA Design Principal

Zaha Hadid, Patrik Schumacher

ZHA Project Director

Woody K.T. Yao

ZHA Project Leader

Simon K.M. Yu

ZHA Competition Team

Hinki Kwong, Melodie Leung, Long Jiang, Zhenjiang Guo, Yang Jingwen, Miron Mutyaba, Pavlos Xanthopoulus, Margarita Yordanova Valova

ZHA Project Team

Hinki Kwong, Jinqi Huang, Bianca Cheung, Charles Kwan, Juan Liu, Junkai Jian, Zhenjiang Guo, Uli Blum, Long Jiang, Yang Jingwen, Bessie Tam, Koren

Sin, Xu Hui, Tian Zhong

Local Executive Architect

AGC Design Ltd. (Hong Kong), AD+RG (Competition Stage) Consultants

Structural & Geotechnical Engineering

Ove Arup & Partners, Hong Kong Ltd.

Building Services Engineering

Ove Arup & Partners, Hong Kong Ltd.

Façade Engineering

Ove Arup & Partners, Hong Kong Ltd.

Landscape

Team 73 Hong Kong Ltd.

Acoustic:

Westwood Hong & Associates Ltd.

Quantity Surveyor

Rider Levett Bucknall Ltd.

Construction

General Contractor

Shui On Construction Company Ltd., Hong Kong

Façade Contractor

YKK AP Facade Hong Kong LTD / Beijing Jangho Curtain Wall Co., Ltd.

Project Data

Site Area: 6600 m2

Construction Floor Area: 28,000 m2

Net Operable Floor Area: 15,000 m2

Floor Levels: 15 Levels + 1 Basement

Floor to Floor Height: 4m (Research + Office), 5m (Design Studio)

Height: 78 meters

Time Spend on Construction: 966 Days

Time Spend on Superstructure: 9 Months

Time Spend on Facade: 15 Months

Project Timeline

June 2007

School of Design Development International

Architecture competition

Dec. 2007

Announcement of the International

Architectural Competition: Zaha Hadid

Jan. 2008

Commencement of Schematic Design

Oct. 2010

Start of Construction

July 2011

Start of Superstructure

May 2012

Topping-out Ceremony

July 2013

Completion of External Facade

Dongdaemun Design Park_Seoul Dongdaemun Design Park_Seoul

Project in figures

Façade System

1 – Fair-faced Concrete (G/F – 3/F)

2 – Aluminum Cladding + Glass Panel (2/F – 5/F)

3 – Semi-unitized Curtain Wall + Feature (3/F – 13/F)

4 – Louvre Wall + Feature (13/F – 15/F)

5 – Roof Aluminum Cladding (14/F -15/F)

6 – Skylight

7 – Glass Reinforced Concrete (G/F – 2/F Ceiling)

Surface Area of Fair-faced Concrete : 3,850 m2

Façade Cladding Area (Aluminum): 6,730 m2

Façade Cladding Unit (Aluminum): 7,033 pc (excl. External Feature)

Façade Curtain Wall Area: 8,140 m2

Façade Curtain Wall Unit: 2,543 pc

Façade Louvre Wall Area: 1,657 m2

Total Length of External Feature :3,670 m

Total Unit of External Feature: 890 Pc

Glass Reinforced Concrete(GRC) Area: 670 m2

Glass Reinforced Gypsum (GRG) Area,Entrance Hall 1,025 m2

Glass Reinforced Gypsum (GRG) Area,Atrium: 2,750 m2

Glass Reinforced Gypsum (GRG) Area,Lecture Theatre: 690 m2

Lecture Hall Seating Capacity: 300 seats

项目来源: Zaha Hadid Architects

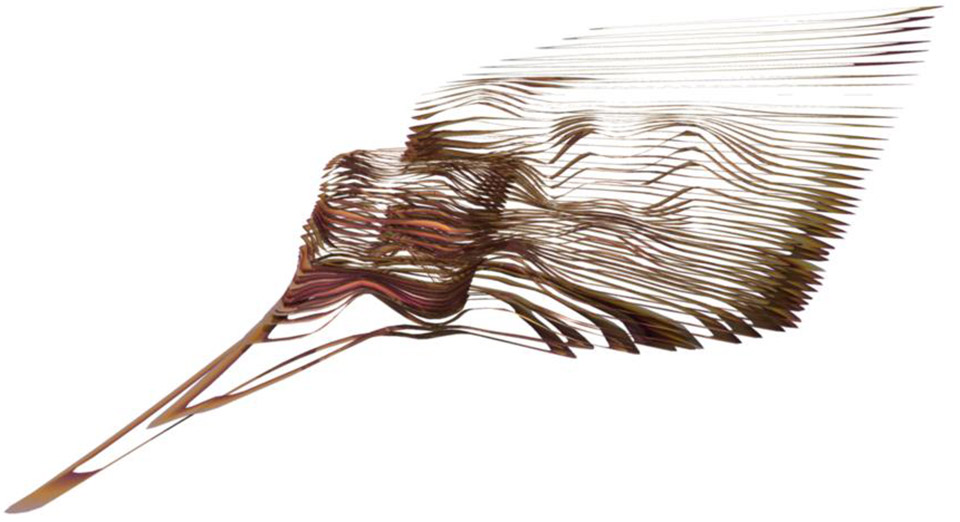

流畅的水平的线条削弱了建筑重量,营造建筑失重的感觉